Mold-in Threaded Stud

Mold-in Threaded Stud

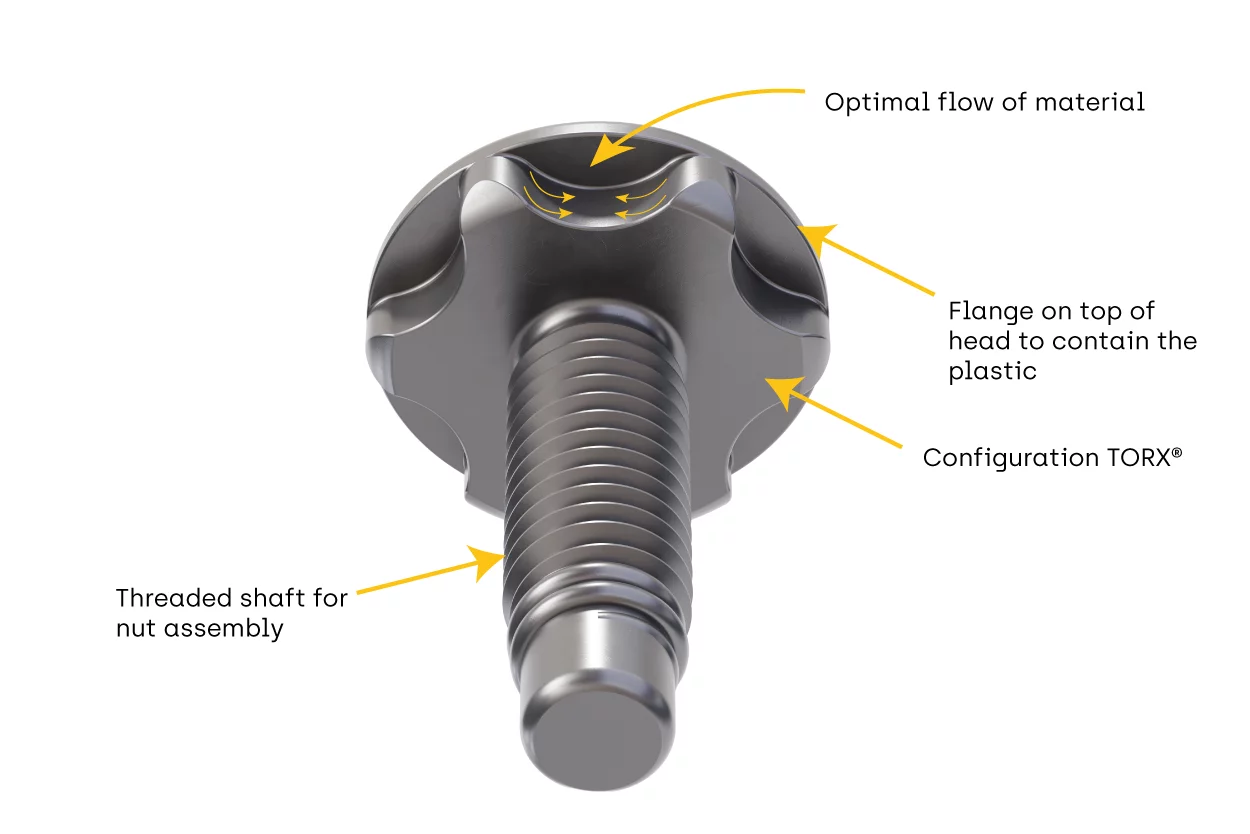

Embedding metal parts — like CELO's PlasTORX® mold-in stud — during the molding process delivers unmatched strength, precision, and design flexibility. Insert molding is becoming more common in a wide range of industries and plastic applications, including e-mobility, automotive, and electronics, due to reduced part weight and effectiveness in tight spaces.

PlasTORX® provides faster production cycles, lower labor costs, and fewer points of failure on the line.

Strong pull-out and rotation resistance

Simple profile reduces design time and costs

Unique TORX® head for optimized plastic flow

Tailored to customer specifications

.png)

We produce PlasTORX® studs on special demand to fit your exact requirements.

PlasTORX® meets technical requirements, reduces costs, and lowers overall part weight, thereby improving performance in automotive applications where every kilogram matters.

Examples: interior components and battery housing

Save space in tight, compact electronics designs without sacrificing strength and durability by molding PlasTORX® studs directly into thin plastic, perfect for housing structures.

Examples: enclosures and junction boxes

For agriculture, appliances, e-mobility, and more, PlasTORX® provides superior, long-lasting strength even in the most demanding conditions. And, with one-on-one support from our engineering team, all mold-in studs can be customized to fit your specific needs.